Application:

Metal Fabrication

Contract welding services

Plant maintenance shops

Processes:

Stick (SMAW)

Flux-Cored (FCAW)

MIG (GMAW)

Pulsed MIG (GMAW-P)

Double Pulsed MIG (GMAW-DP)

Input Power:

1PH ~ 230V ±15%

3PH ~ 400V ±15%

3PH ~ 230V/400V ±15%

Amperage Range: 10-250A

Rated Output at 40℃ (104℉):

250A at 26.5V @60% Duty Cycle

Weight: 52KG

Advanced Features

Simple Operation but More Compatible

3 Steps to achieve weld perfection

1. Select operation mode.

2. Select Job-list No.

3. Adjust welding current.

Always the perfect setting by the synergic function using the material thickness.

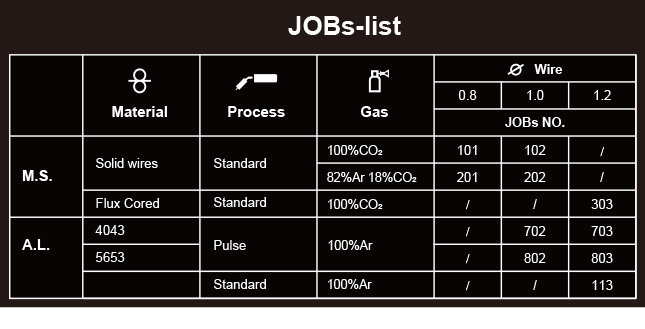

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface. We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and aluminum alloys. Operation is easier than ever before.

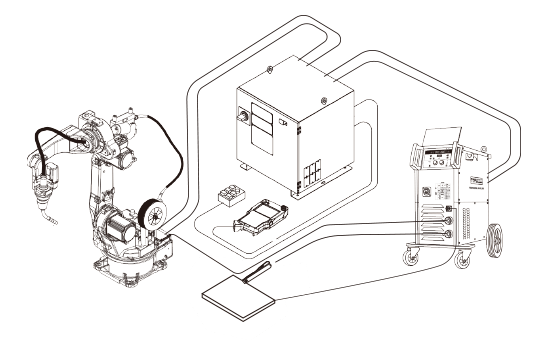

Robotic with advanced MIG process package, achieve ultra-high efficient welding with perfect welding performance. Optional package for robot interface by Analog connectors or Digital ports including EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485 etc.

| Robot Welding Requirement | |

|---|---|

| Synergy Control | ● |

| Pulse MIG | ● |

| Double Pulse MIG | ● |

| ULS | ○ |

| HSS | ○ |

| ● Standard options | ○ Optionally available |

The PROMIG 250XP offers a wider range of voltage options to meet the different voltage requirements of personal or industrial welding scenarios. You can choose a single-phase welding machine for personal use, or you can choose a three phase high rated voltage, which is suitable for many industries such as automotive, container, steel structure and shipbuilding.

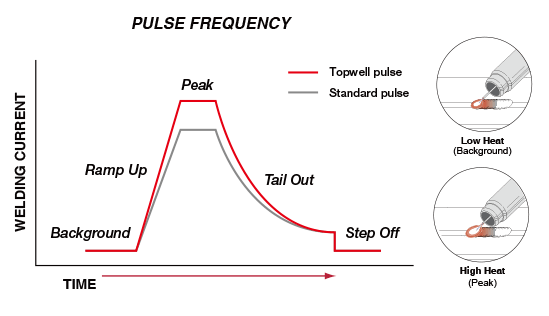

Better Aluminum Welding Process

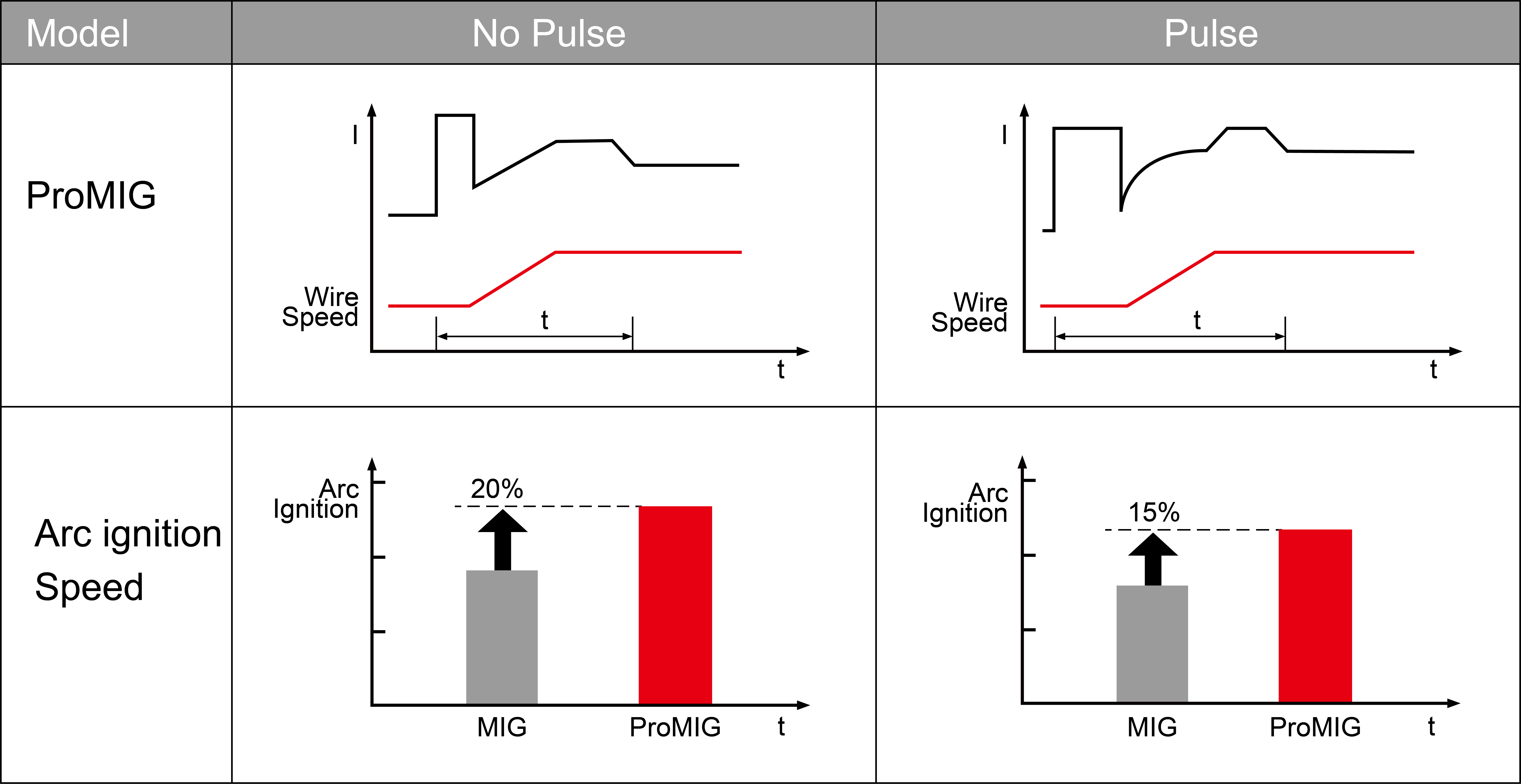

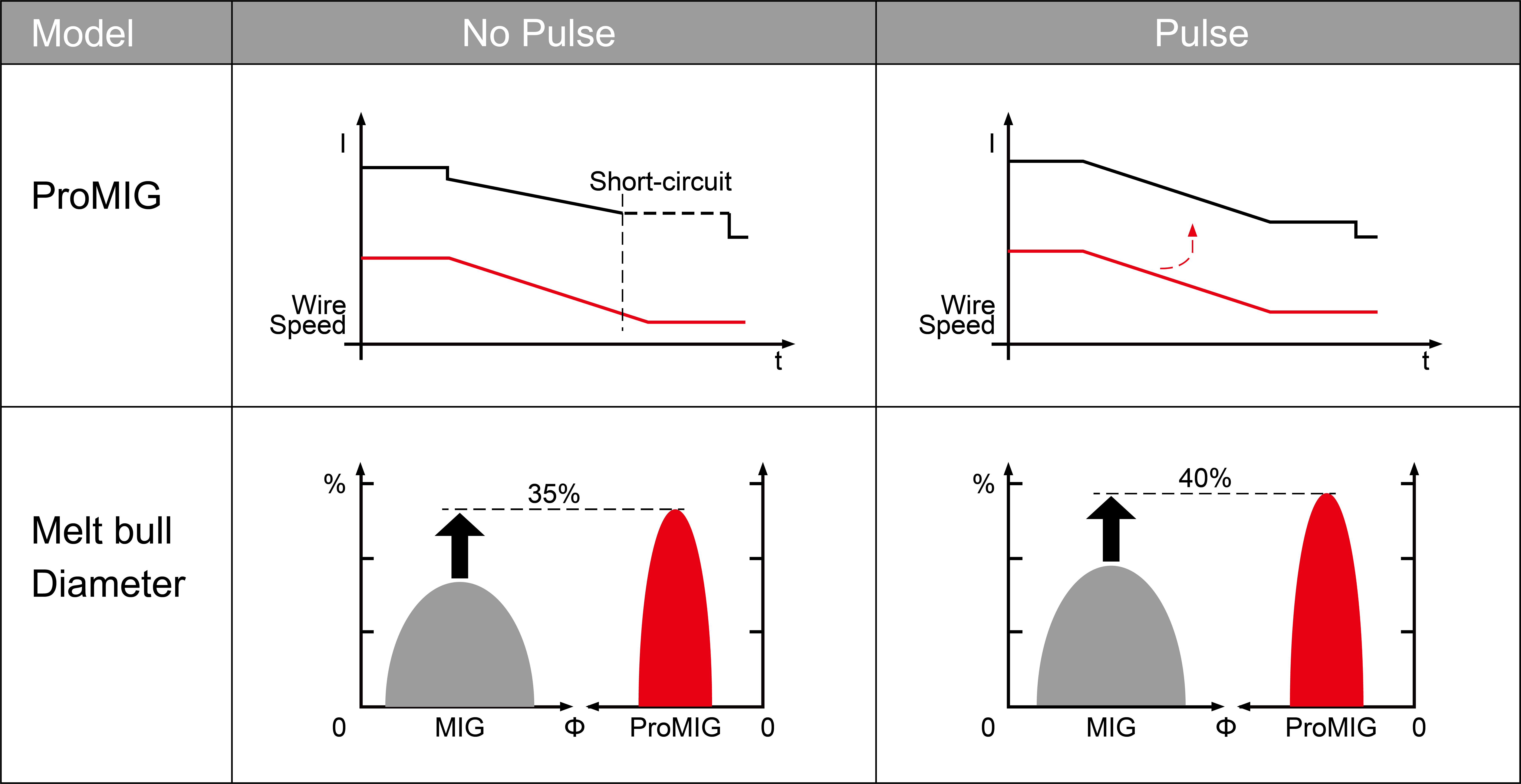

The PROMIG 250XP is an upgraded module and machine that is compatible with more advanced pulse processes. The PROMIG 250XP improves on the standard pulsing process to provide a higher peak current and a larger current difference that is more suitable for aluminum alloy welding. As wire speed increases/decreases, the pulse or MIG parameters also increase/ decrease to match the right amount of power needed to achieve a more perfect welding curve.

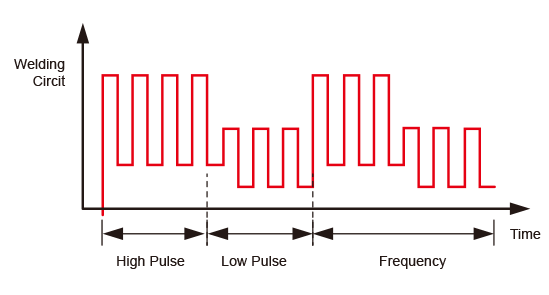

The double pulse is a combination of the Pulse MIG process and the variation of the high and low currents, with the low pulse section providing cooling time to the melt pool while simulating the oscillation so that the melt pool oscillates.So no need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework for Aluminum sheets.

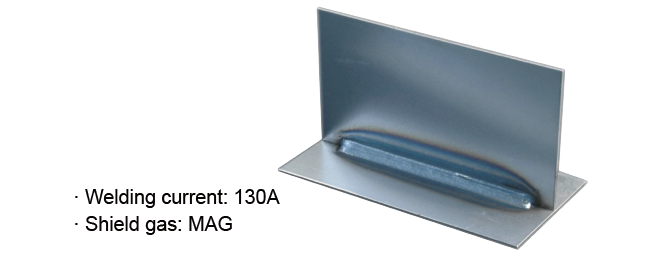

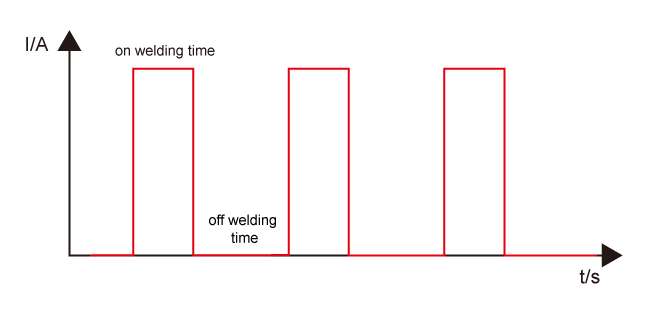

HSS is the high speed spot welding, which is perfectly combining the welding process, arc physics, high dynamic power response and powerful motor control technology, short in arc ignition time and arc ending time, a welding spool can be formed swiftly. A spot welding cycle is quickly completed, cycle over and over, by adjusting the time gap with the robot to get the fish scale you wish, weld seam is clear and beautiful.

Advanced Technologies for Further Heat Control

The ULS process is a modified short-arc transfer arc with perfect waveform setting that greatly reduces spatter generation. In the pinch phrase, there is a special current interruption, the energy is extracted under the program setting, avoiding the explosion caused by the large current, and the surface tension of the molten pool warms the generated droplets. Even in CO2 and MAG welding, it can minimize the spatters, which means less rework, fewer rejects, less cleaning required and savings on wearing parts.

HSS is the high speed spot welding, which is perfectly combining the welding process, arc physics, high dynamic power response and powerful motor control technology, short in arc ignition time and arc ending time, a welding spool can be formed swiftly. A spot welding cycle is quickly completed, cycle over and over, by adjusting the time gap with the robot to get the fish scale you wish, weld seam is clear and beautiful.

Tack welding: by robot

Widely applied on the thin (≤2mm thickness) pipes or frame/structure welding jobs.

Improved Operation Process & Controls

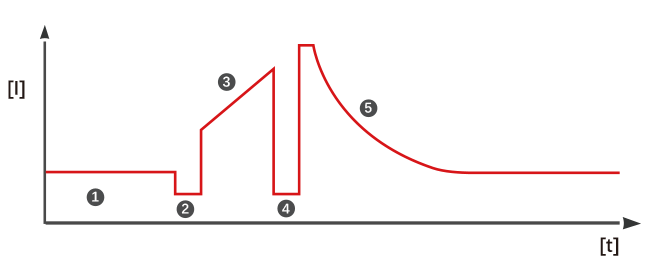

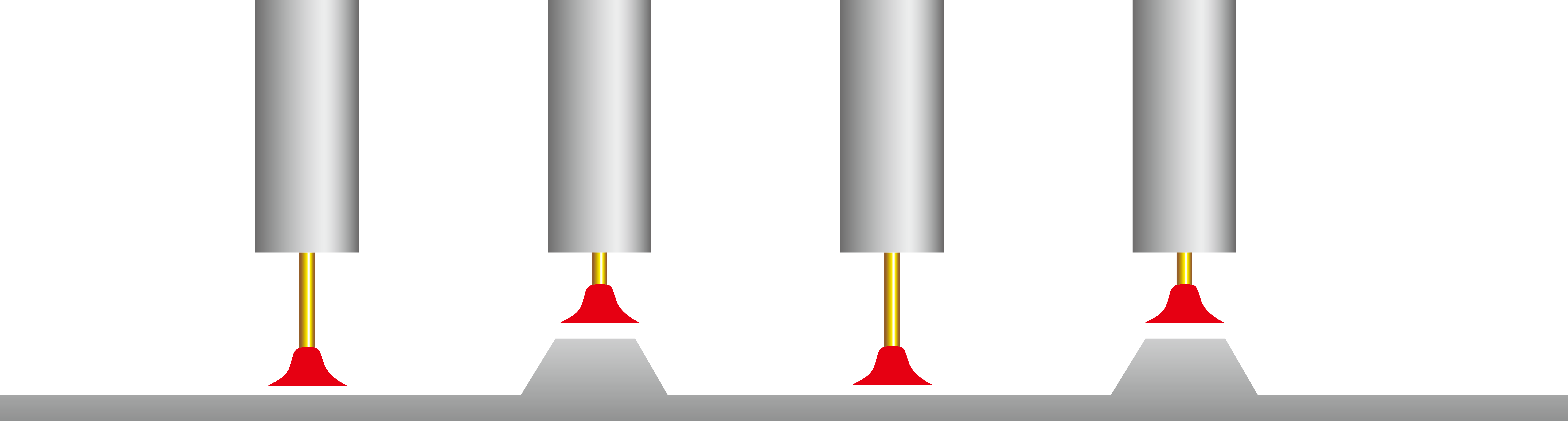

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

By changing the distance between torch and workpiece. You can now react much more easily to control the arc, such as changing gap dimensions or arc blow, more intuitively and with greater efficiency !

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

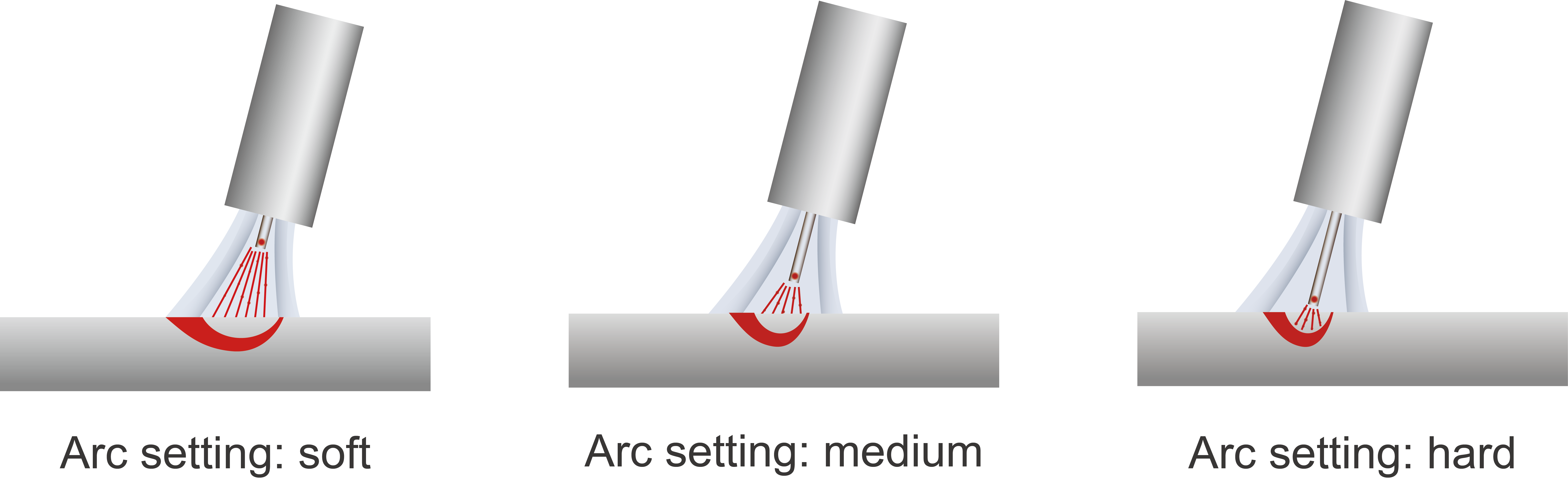

Dynamic control allows the welder, for the first time, to variably adjust a pulse welding machine to a wide range of jobs and welding positions as well as to his personal preferences. The welder can use a controller to directly access the arc characteristic and change it from soft to hard.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号